AWWA Knife Gate Valves — Reliable Solutions for Water Systems by VTORK CONTROLS

AWWA knife gate valves are vital components in water, wastewater, and sludge water systems, offering robust performance and precision in critical applications. V-TORK designs these valves following the American Water Works Association (AWWA) standards, ensuring reliability, durability, and superior sealing capabilities.

Why Choose V-TORK AWWA Knife Gate Valves?

- AWWA Compliance: Manufactured to meet stringent AWWA standards for water applications.

- Durable Construction: Stainless steel, cast iron, or ductile iron bodies with resilient or metal seats.

- Versatile Applications: Ideal for water, wastewater, and sludge water systems.

- Custom Designs: Bonneted and bonnetless options with uni-directional and bi-directional flow configurations.

Types of V-TORK AWWA Knife Gate Valves

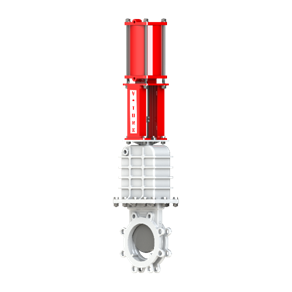

U-106 — Uni-Directional, Wafer Type Bonneted Knife Gate Valves

Features:

- Compact wafer design for easy installation in tight spaces.

- Bonneted structure for minimal leakage and enhanced durability.

- Resilient seating for excellent sealing against water and wastewater.

- Applications: Suitable for water treatment plants, sludge systems, and clean water pipelines.

|

| Uni-Directional, Wafer type Bonnetted Knife gate valves |

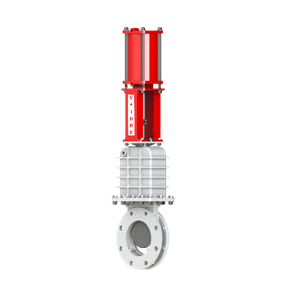

U-205 — Uni-Directional, Lug Type Bonneted Knife Gate Valves

Features:

- Lug type design ensures secure installation with easy pipeline isolation.

- Bonneted configuration reduces maintenance and protects internal components.

- Optimal for handling wastewater and sludge water applications.

- Applications: Widely used in municipal water systems and wastewater facilities.

|

| Uni-Directional, Lug type Bonnetted Knife gate valves |

U-304 — Uni-Directional, Flanged Type Bonneted Knife Gate Valves

Features:

- Flanged connections ensure robust installation and alignment.

- Bonneted design enhances durability and minimizes leakage.

- Excellent for managing water flow in critical systems.

- Applications: Suitable for large-scale water distribution networks and sludge processing.

U-403 — Uni-Directional, Flanged Type Bonneted/Bonnetless Knife Gate Valves

Features:

- Flexible design available in bonneted or bonnetless configurations.

- Flanged ends provide reliable sealing and installation.

- Suitable for water and wastewater applications requiring precise flow control.

- Applications: Ideal for sludge treatment plants and industrial water systems.

|

| Uni-Directional, Flanged Type Bonnetted/ Bonnet Less Knife gate valves |

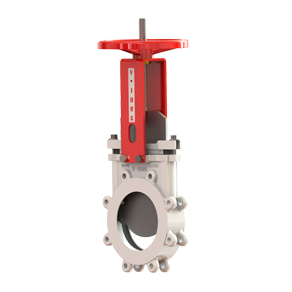

B-270 — Bi-Directional, Lug Type Resilient Seated (U Seal)

Features:

- Bi-directional flow design for versatile use.

- Lug type connection ensures robust performance under high pressures.

- Resilient U-seal provides bubble-tight shutoff in demanding applications.

- Applications: Used in water treatment, wastewater handling, and industrial water processes.

|

| Bi Directional, Lug Type Resilient Seated (U Seal) |

Key Advantages of V-TORK AWWA Knife Gate Valves

- Reliable Sealing: Resilient and metal seats ensure leak-proof operation.

- Long Service Life: High-quality materials withstand corrosion and abrasion.

- Flexible Designs: Bonneted and bonnetless options to suit various operational needs.

- Low Maintenance: Engineered for easy installation and minimal upkeep.

Applications of AWWA Knife Gate Valves

- Water Treatment Plants: Precise flow control for clean water systems.

- Wastewater Management: Efficient handling of sludge and corrosive media.

- Municipal Water Systems: Reliable performance in large-scale distribution.

- Industrial Water Applications: Suitable for complex industrial processes.

Maintenance Tips for AWWA Knife Gate Valves

- Inspect Regularly: Check for wear on seals and seats to prevent leakage.

- Lubricate Moving Parts: Ensure smooth operation of the stem and actuator.

- Clean Valve Internals: Remove any sludge buildup for optimal performance.

- Schedule Maintenance: Periodic checks reduce downtime and enhance longevity.

V-TORK: Your Trusted AWWA Knife Gate Valve Manufacturer

As a leading knife gate valve manufacturer in India, V-TORK delivers top-quality solutions for water, wastewater, and sludge systems. Whether you need uni-directional wafer valves or bi-directional resilient seated valves, we ensure precision engineering and long-lasting performance.

Explore Our Range of AWWA Valves

Visit V-TORK Controls to learn more about our comprehensive range of AWWA knife gate valves or request a quote tailored to your needs. Experience unmatched quality and service with V-TORK products.

Comments

Post a Comment